UV Weathering

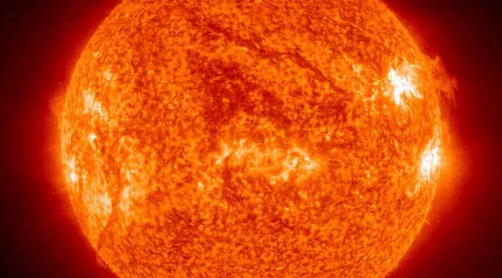

Marlen Textiles is pleased to bring you another quick “course” from Textile U. This month, learn all about “UV Weathering” or in laymen’s terms how and why the sun fades and damages materials.

If you use fabrics to protect or cover, then you know the power of the sun can fade colors. But the serious damage that comes from the sun is unseen; with effects that weaken, break down and undermine a fabric’s original purpose, to protect from the elements.

Ultraviolet (UV) radiation from the sun, delivered as regular sunlight, can lead to decreased performance and undesirable appearance and detrimental changes to the fabrics original specifications, both coated and uncoated fabrics. UV radiation can cause harm by breaking down the chemical bonds in a polymer’s structure, a process referred to as photodegradation. For a coated fabric, this degrades the binder and can lead to such changes as cracking, loss of gloss, chalking, pigmented fading, delamination or peeling, yellowing, and loss of physical and protective properties of the coating. Cracking is caused by polymer chain scission allowing loss of strength of the base fabric. Chalking eventually results in reduced adhesion of the topcoat followed by delamination. It could also increase water permeability of the coating. Binder photodegradation can lead to the formation of chromophores, or color bodies, which yellow the coating (Additives for Coatings-CIBA). Uncoated fabrics also are subject to the effects of UV radiation by materially changing the fiber the yarn is spun from. These products see decreased tear strength, abrasion resistance, water resistance, etc after prolonged exposure.

The phrase “UV absorbers” (UVA), is a general term encompassing three different stabilizing additives: UV Absorbers, Free Radical Terminators (HALS), and Antioxidants. Traditionally UVA and HALS are used in combination to provide the most synergistic results for protecting fabric from compositional changes when exposed to heat, light, air, water, radiation, or physical stress.

Hindered Amine Light Stabilizers (HALS) act as an inhibitor to photochemically initiated degradation by slowing the reaction. HALS form free radical scavengers and lead to reduced oxidation and ultimately protect the polymer/coating from degradation. HALS work on the surface to prevent scratches, mar, and de-lamination and are regenerated rather than consumed in the process which provides high efficiency protection and extreme longevity.

One way to fight this is by the use of UV Absorbers. UV Absorbers have a separate role in protection from harmful wavelengths. UVA additives absorb radiation by filtering out long wavelengths and distributing it as thermal energy. UV Absorbers work to prevent photochemical reactions leading to degradation of the coating and base fabric but do not protect from surface defects. The photo permanence or the resistance of the additive itself to degradation is dependent on the type of UVA chosen for each particular application.

Antioxidants are the third type of stabilizing additive that works in a similar way to HALS by reducing oxidation. Antioxidants terminate chain oxidation reactions by removing free radical intermediates, so reducing agents are often used for this type of protection.

Click here to View and download a helpful Technical Bulletin:

Sunlight, Weathering & Light Stability Testing